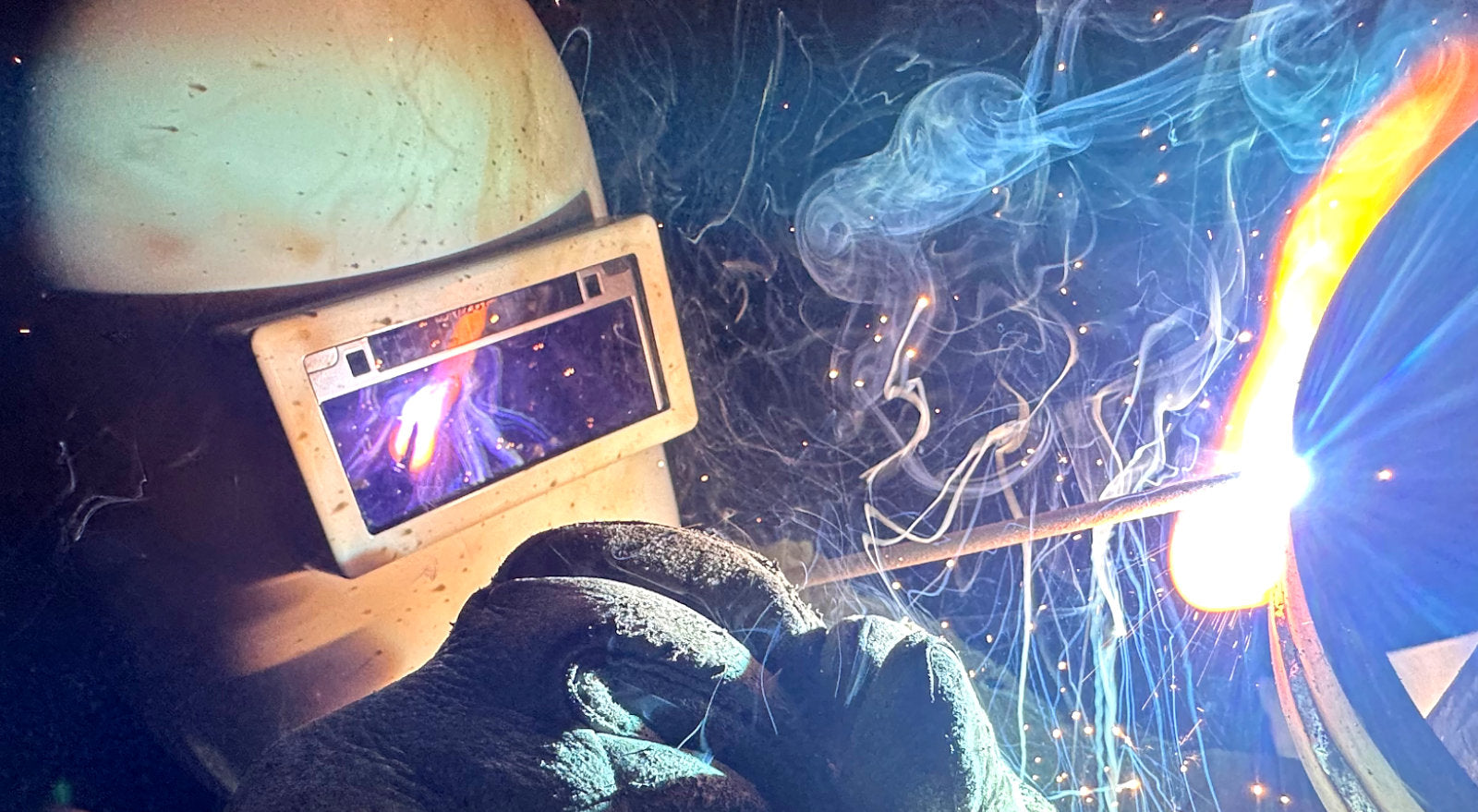

If you've ever wondered what it's like under a welding helmet, we developed a system to capture images showing exactly what an experienced welder sees while welding.

What You See Through a Welding Helmet

Under the arc-light, there is an alien world only a welder can see. It can be surprisingly peaceful, even beautiful, despite its intensity.

*weld puddle pictures taken through our multi-shade welding lens.

How it looks depends on the type of welding. But before we get into that, let's explain what you are looking at.

What is a Weld Puddle?

The melted metal a welder moves around to fuse pieces of metal together is called a weld puddled (sometimes called a weld pool).

The metal is usually melted with an electric arc. Think of it like a small lightening bolt. The arc creates a source of heat causing the metal to rise above its melting point and form a liquid puddle of molten metal.

How Does a Welder See the Puddle?

The welding arc is bright, think high-beams at night, which is why you only see light and sparks in movies when welding is featured. But a welder has a different view.

Welders wear special helmets or hoods with a lens that filters light (image above shows modern vs traditional lens). They look through the lens when welding, which blocks the brightest part of the arc light and lets the puddle appear.

Why Can't I See While Welding?

Seeing what you're welding comes down to two things: knowing where to look and finding the right welding lens.

Use your peripheral vision to watch the puddle. If the fovea of your eye (where you see high detail) crosses the arc-light, your vision will wash out, like walking into a dark room after shining a flashlight in your eyes.

The weld above is moving down and forward. The arrows show where to visually pay attention to, along with watching the puddle.

Find a welding lens that works for you. Think about what color sun glasses you like as a starting point, since welding lenses come in many tints. Experiment with the intensity of the shade you use. Shade 9, 10, and 11 are common.

What are the Main Types of Welding and What do They Look Like?

Each type of welding looks different. There are many welding processes and opinions differ on how many to include in lists of the most common.

Here we'll focus on the three almost everyone is exposed to in welding school. Stick welding, MIG welding, and TIG welding. If you know a professional welder, it's likely he or she is doing one or all three of these.

All three use an electric arc to melt metal, but they differ in the specifics of how the arc is created, how new metal is added to the weld puddle, and how the hot weld is protected from the atmosphere (molten metal reacts with air, contaminating it, so it needs to be protected by another gas while welding).

What is stick welding?

Stick welding or SMAW (shielded metal arc welding) is the oldest electric arc welding process. It's also the simplest process on this list to set up, because it doesn't need a bottle of compressed gas to protect the molten puddle.

You hold a covered metal rod, called an electrode, in a stinger. This forms half of an electric circuit. A ground clamp is hooked to the base metal, which completes the circuit when you "strike an arc" by contacting the electrode to the base metal.

The metal core in the electrode conducts electricity and melts off to form filler metal for the weld deposit. It's covered in a coating (a flux) that burns off while welding, stabilizing the arc and producing gas (like CO2) that shields the weld puddle.

If you want to dive in deeper, The Fabricator has a great article on stick welding (opens in new window).

What does stick welding look like?

Behind the smoke and sparks, the stick puddle glows beneath a layer of swirling flux. It's the hardest on the list to see while welding. Below you can see the puddle spread out around the arc as metal is deposited.

What is MIG welding?

MIG welding or GMAW (gas metal arc welding) is considered the fastest and easiest welding process to learn. But it takes knowledge and experience to get the machine set up right for either of these to be true.

A welding gun continuously feeds a wire through a nozzle into the weld pool, which is why it's often called "wire welding." The nozzle also emits a shielding gas.

It's the trickiest on the list to setup correctly but easiest to manipulate and control. Miller has a good overview of MIG welding (opens in new window) with links to help setup your machine.

What does MIG welding look like?

MIG produces a creamy fluid puddle that's easier to see, because it has less smoke, than stick welding. You can see the rim of the nozzle and wire feeding into the puddle below.

What is TIG welding?

TIG welding or GTAW (gas tungsten arc welding) requires the careful and controlled use of your hands. It's the most precise form of welding on the list.

It's also the only process on the list that doesn't use the electrode as filler metal. A shaft of tungsten, which conducts the arc, is held in a torch which also emits an inert gas (usually argon). The filler metal is added separately.

If you want to learn more, WeldGuru has an excellent overview of TIG welding (opens in new window).

What does TIG welding look like?

The TIG puddle is easy to see because there is no smoke or sparks, but it looks different depending on the metal being welded.

Besides looking different, TIG welding requires slightly different technique depending on the metal. It's similar with steel and stainless; but when it comes to aluminum, a different approach is necessary. Check out our Aluminum TIG guide to learn more.

What's the Easiest Welding Process to See?

Of the three types of welding we've talked about, TIG is the easiest to see while welding, but that doesn't make it the easiest process to learn. Or does it?

Being able to see the weld puddle is a critical part of learning how to weld, and it's something many beginners struggle with. TIG is a precise process, so it's not considered easy to learn. But it depends on what your own strengths and weaknesses are, and to what degree being able to see the weld puddle is posing difficulty.

If you want to learn about how to TIG weld, check out our article on the fundamental TIG variables.